WHAT IS A RANDOM QUALITY INSPECTION?

Random Quality Inspection means our inspector selects from the whole quantity of your order a sampling lot, a small quantity of products that will be controlled visually and functionally. The result of that small quantity of finished products should represent the overall quality of your whole order according to the international AQL quality control method MIL-STD-105E / ISO 2859-1.

Random Quality Inspection, or random sampling quality inspection, is the most used and common quality control method in China and Asia right now, for the last decade. All the quality inspection companies usually use it as the quality inspection method.While it is a worldwide renown method, this method purpose is more to give customer a tendency of the quality of the full batch of a production. It will not be as certain and detailed as a Full 100% Quality Inspection, but it is a very good indicator of goods quality when performed as a pre shipment inspection China or Asia. At the same time , it is a cheaper inspection service method that requires most of the time only 1 day of control and can quickly help customer know if the whole order is quality compliant or not.

Random Quality Inspection, or random sampling quality inspection, is the most used and common quality control method in China and Asia right now, for the last decade. All the quality inspection companies usually use it as the quality inspection method.While it is a worldwide renown method, this method purpose is more to give customer a tendency of the quality of the full batch of a production. It will not be as certain and detailed as a Full 100% Quality Inspection, but it is a very good indicator of goods quality when performed as a pre shipment inspection China or Asia. At the same time , it is a cheaper inspection service method that requires most of the time only 1 day of control and can quickly help customer know if the whole order is quality compliant or not.

Benefits of a Quality Inspection for Your Company

- Get maximum customers satisfaction : By booking an inspection , you maintain a constant pressure on your China or Asia suppliers, and make sure they deliver good quality products. In the end, your existing customers will see you as a great supplier yourself and will want to work with you for the long term

- Boost your sales by having a top quality reputation : By being viewed as a top QUALITY supplier in your industry, you'll close even more new potential customers.

- Save A LOT of Money : spending 299USD for a pre shipment quality inspection in China or Asia while the goods are still in Asia is priceless. It helps you find early potential issues, or even better prevent issues, and can save you THOUSANDS or TENS of thousands USD. Finding about issues when goods are at your warehouse can cost you a fortune to fix.

- Make sure you always work with reliable China & Asia suppliers : If during each inspections we find quality issues, you'll know that your supplier might be trouble & put you in danger toward your customers. But the opposite is true also, if your supplier successfully passes inspections, then you can be confident it's a good source for your business

OUR PRICING

During our Inspections, we inspect for you 60% More Products than any other western inspection company in China, Vietnam, Cambodia, Thailand & Bangladeshwith No additional charge

|

|

For regular customers with monthly inspections, we also propose great discount prepaid packages of 5, 10 or 20 inspections

WHAT DOES AQL MEANS?

AQL means "Acceptable Quality Limit" or "Acceptance Quality Level". AQL is a recognized international method for random sampling quality inspection, that comes with predefined sampling quantities to inspect as well as predefined levels of acceptance for maximum defects quantity.

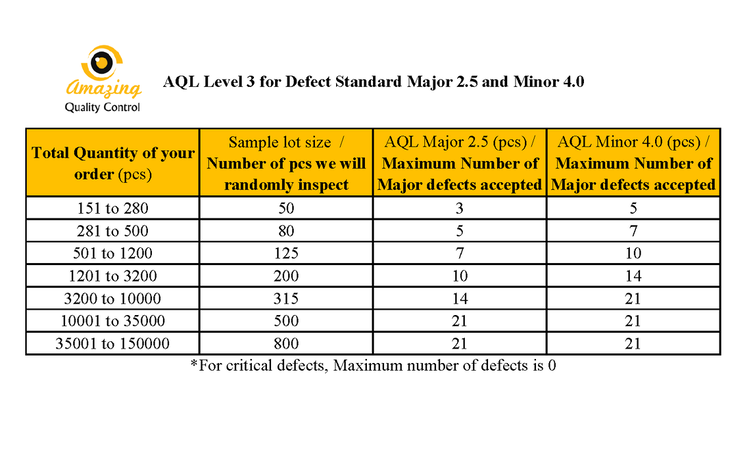

Depending on how many pieces is your order total quantity, we look at the AQL table and first define how many pieces we will need to check,which is the inspection sampling quantity.Then for each sampling quantity, the AQL table will enable us to know what is the maximum acceptance during inspection for critical, major and minor defects. After completion the inspection, If the quantity of defect is inferior to the AQL maximum limit, then basically it means your order is quality compliant. On the other hand, if after completion of the inspection the quantity of defects is superior to the AQL maximum limit, then it means there are quality issues that might prevent you for accepting the shipping of the goods.

Currently all the professional third party inspection companies are using the AQL standard for factory inspection in China.

SEE HOW MANY PIECES WE WILL CHECK FOR YOU COMPARED WITH OTHER INSPECTIONS COMPANY IN ASIA

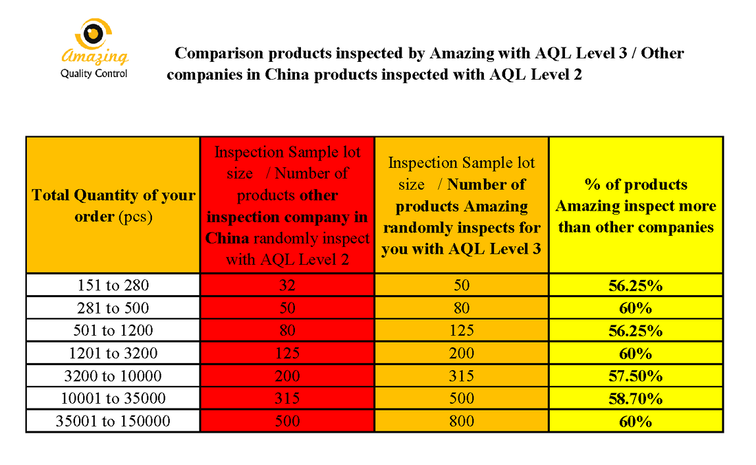

We at Amazing perform all of our inspections with AQL standard highest sampling level, Level 3, while All of other inspection companies in China & Asia use a lower, less inspected quantity level 2. Simply put , that means that We randomly select & inspect for you 60% more products than any other inspection company, without charging you more.

Below you'll find an AQL table showing you the huge difference between how many pieces we inspect and how many pieces other companies inspect.

Below you'll find an AQL table showing you the huge difference between how many pieces we inspect and how many pieces other companies inspect.

Below you'll find The AQL table we are using for random quality inspection. See how many pieces we will inspect for you and what will be the maximum defects Acceptance Quality Level for your order inspection

RANDOM INSPECTIONS CAN BE CONDUCTED AT ANY STAGE OF THE PRODUCTION

Production Start

|

During Production

|

Pre Shipment

|

SEE WHAT A REAL RANDOM INSPECTION REPORT LOOKS LIKE

HOW DO WE CALCULATE THE RANDOM QUALITY INSPECTION FINAL PRICE?

The Random quality inspection final price is calculated according to the quantity of work that will be needed.That quantity of work will be charged to you by man day , which means by day of work by inspector.

Now usually for simple products or small quantity products, 1 man day is enough. Nevertheless for bigger quantity or complex products we might need more than 1 inspector to perform the control.So the total final cost of the Random Inspection will depend on the 2 below criterias :

Now usually for simple products or small quantity products, 1 man day is enough. Nevertheless for bigger quantity or complex products we might need more than 1 inspector to perform the control.So the total final cost of the Random Inspection will depend on the 2 below criterias :

- The quantity of products to control according to the AQL Table :The more products to control, the more work is to be done

- The complexity of the product : products are not equal when we talk about quality control. Some products might be very simple to control with only a visual inspection requested, while other products category like electric or electronic products might need deep function testing